assignment2 <<

Previous Next >> DigitalProductCollaboration

Product design process

Collaborative product design processes of industrial design and engineering design in consumer product companies

產品公司中的工業設計和工程設計的協作產品設計過程

This study aims to elucidate how industrial designers and engineering designers collaborate, and how such an alliance reflects in the design process. We conducted in-depth interviews about actual product design projects with 34 industrial and engineering designers from six consumer product manufacturers. We firstly identified individual design processes from the interview data. Secondly, we then compared and merged the design processes into collaborative processes using a mosaic method. We finally simplified the collaborative processes to create representative process models. As a result, we discovered four types of typical collaborative product design processes and their characteristics e Type 1: ID-led Concept-driven Process, Type 2: ID-led Combined Outside-inside Process, Type 3: ED-led Inside-first Process, and Type 4: ID&ED Synergetic Process.

這項研究在闡明工業設計師和工程設計師如何協作,以及這種合作如何體現在設計過程中。我們與來自六個產品製造商的34名工業和工程設計師進行了有關實際產品設計項目的深入採訪。我們首先從訪問數據中識別出各個設計過程。其次,我們使用鑲嵌的方法將設計過程進行比較並合併為協作過程。最後,我們簡化了協作流程,以創建具有代表性的流程模型。結果,我們發現了四種類型的典型協同產品設計流程及其特徵:e類型1:由ID主導的概念驅動過程,類型2:由ID主導的內外聯合過程,類型3:由ED主導的由內到外的流程,類型4:ID&ED協同流程。

Integrated contribution of engineering design and industrial design is essential to launch successful products to the market. Product design can hardly be explained from a mono disciplinary perspective. However, it is known that engineering design and industrial design have considerably different design practices (Pei, 2009; Persson & Wickman, 2004), and their design approaches are in some ways opposite to each other (Eder, 2013; Hosnedl, Srp, & Dvorak, 2008; Pahl, Wallace, & Blessing, 2007). The indus- trial designers’ role includes enhancing user experience of a product and developing its outside form and interface (Ulrich & Eppinger, 2012). They employ knowledge and skills in aesthetics and ergonomics (Eder, 2013; Pahl et al., 2007). Under the interaction with industrial designers, engineering designers take part in implementing the design concept developed by indus- trial designers (Persson & Warell, 2003). Engineering designers provide a means for the product to be functioning, reliable, and manufactured (Hubka & Eder, 2012; Pahl et al., 2007). This leads to different approaches between industrial and engineering designers (Cross, 2008; Hubka & Eder, 2012).

工程設計和工業設計的綜合貢獻對於向市場推出成功的產品至關重要。從單學科的角度很難解釋產品設計。但是,眾所周知,工程設計和工業設計在設計實踐上有很大不同(Pei, 2009; Persson & Wickman, 2004),並且它們的設計方法在某些方面是相衝突的(Eder, 2013; Hosnedl, Srp, & Dvorak, 2008; Pahl, Wallace, & Blessing, 2007)。工業設計師的角色包括增強產品的用戶體驗並開發其外部樣式和界面(Ulrich & Eppinger, 2012)。他們運用美學和人體工程學方面的知識和技能(Eder, 2013; Pahl et al., 2007)。在與工業設計師的互動下,工程設計師參加了由工業設計師提出的設計概念的實施(Persson & Warell, 2003)。工程設計人員為產品的功能,可靠和製造提供了一種方法(Hubka & Eder, 2012; Pahl et al., 2007)。這導致了工業和工程設計師之間的有不同觀點(Cross, 2008; Hubka & Eder, 2012)。

It is often argued that engineering designers use an ‘outward approach e developing from function to appearance’ whereas industrial designers follow an ‘inward approach e developing from appearance to functions’ (Eder, 2013; Hosnedl et al., 2008; Pahl et al., 2007). With these notions, the following two design strategies were proposed: one is the ‘inside-out’ strategy that is defined as designing the inner working parts first, and thus constraining the outside shape, and the other is the ‘outside-in’ strategy where the envelope was defined first, and thus constraining the inside parts (Hubka & Eder, 2012; Kim & Lee, 2010). These design strategies refer to combined design pro- cesses that a company should take for a specific purpose with particular con- ditions. However, little is known from empirical evidence about how these two strategies are applied in projects in industry. There have been few attempts to view the design process from an integrative perspective of engineering design and industrial design. In this regard, we investigated the collaborative design processes of both disciplines in the industrial context.

經常有人爭辯說,工程設計師使用”從外觀到功能發展的方式”,而工業設計師則採用``從外觀到功能發展的方式'(Eder, 2013; Hosnedl et al., 2008; Pahl et al., 2007)。基於這些概念,提出了以下兩種設計策略:一種是“由內而外”的策略,定義為首先設計內部工件及配件,從而限制外部形狀,另一種是“由外而內”的策略。首先定義外型,然後約束內部零件(Hubka & Eder, 2012; Kim & Lee, 2010)。這些設計策略涉及公司應在特定條件下為特定目的而採取的設計過程。但是,從經驗來看的證據中很少了解到這兩種策略如何在工業項目中應用。很少有嘗試從工程設計和工業設計的綜合角度來看待設計過程。在這方面,我們研究了工業環境中兩個學科的協作設計過程。

The research questions were: 1) what types of collaborative product design processes exist, and 2) what conditions drive a company to adopt a particular type of process. Based on the two designer groups’ roles and characteristics, we hypothesized that there would be different types of outside-in and inside- out design approaches. We assumed that the outside-in approach would be characterized by an industrial design-led design process, thus generating in- dustrial designer’s role as a requirement and criteria provider, and the inside-out approach would be an engineering design-led design process, where engineering designers restrict industrial designer’s task range by providing initial requirements for industrial designers’ responsibilities. In or- der to succeed in a highly competitive market, companies should create collaborative processes of industrial design and engineering design by prop- erly adopting outside-in and inside-out approaches to match their situations and objectives.

研究的問題是1:存在哪些類型的協作產品設計流程,以及2:什麼條件促使公司採用特定類型的流程。根據這兩個設計師小組的角色和特點,我們假設會有不同類型的由內而外的設計方法。我們認為,由內而外的方法將以工業設計為主導的設計過程為特徵,從而產生工業設計師作為需求和標準提供者的角色,而由內而外的方法將以工程設計為主導的設計過程,工程設計師通過提供對工業設計師職責的初始要求來限制工業設計師的任務範圍。為了在競爭激烈的市場中取得成功,公司應通過適當地採用從內而外的方法來匹配其情況和目標,從而創建工業設計和工程設計的協作流程。

This paper serves two goals: firstly, to shed light on the form of the original collaborative product design process applied in practice, and secondly to determine different types of processes used for different purposes under different conditions. For these purposes, we conducted in-depth interviews with industrial designers and engineering designers from six consumer product manufacturers. We determined each company’s product design processes us- ing a ‘mosaic method,’ where individual design processes drawn from interview data were combined to complete a collaborative process. As a result, we iden- tified four types of typical collaborative product design processes and their characteristics.

本文有兩個目標:首先,闡明在實踐中應用的原始協作產品設計過程的形式;其次,確定在不同條件下用於不同目的的不同類型的過程。為此,我們對六家消費產品製造商的工業設計師和工程設計師進行了深入採訪。我們使用“mosaic method”確定了每家公司的產品設計流程,其中結合了從訪談數據中提取的各個設計流程以完成協作流程。結果,我們確定了四種典型的協作產品設計流程及其特徵。

The recurring term ‘collaborative product design’ throughout this article refers to a product design created by the collaborative contribution of industrial design and engineering design. In particular, in corporate contexts, collabora- tive product design involves a series of design activities, such as the creation of initial product concepts, decisions on interior specifications, and the develop- ment of outer forms and inner structure. Hence, ‘collaborative product design process’ means the product design process in which both industrial design and engineering design are directly involved in product development activities.

在本文中,“協同產品設計”的用語是指通過工業設計和工程設計的共同貢獻而創建的產品設計。特別是在公司環境中,協同產品設計涉及一系列設計活動,例如:創建初始產品概念,確定內部規格以及開發外部特徵和內部結構。因此,“協同產品設計過程”是指工業設計和工程設計都直接參與產品開發活動的產品設計過程。

‘Industrial design’ at this point mostly concerns developing the outer forms, in- terfaces, and user experience of consumer products, excluding graphic-only or styling-only design. ‘Engineering design’ develops technical solutions for placing and operating internal functional parts in consumer products and defines inter- nal and external parts constituting products in a way that enables mass produc- tion. We labelled engineers engaged in such activities as ‘engineering designers’.

This article consists of three parts: The first part describes the research approach in detail. The second part presents typical collaborative product design processes and their characteristics as findings. Finally, it summarizes the results, and dis- cusses the implications and contribution to the design literature.

此時的“工業設計”主要涉及開發產品的外形,界面和用戶體驗,但不包括純圖形或純樣式的設計。 “工程設計”開發了用於在產品中放置和操作內部功能部件的技術解決方案,並以能夠實現大規模生產的方式定義了構成產品的內部和外部部件。我們將從事此類活動的工程師標記為“工程設計師”。

本文包括三個部分:第一部分詳細介紹了研究方法。第二部分介紹了典型的協作產品設計過程及其特徵。最後,它總結了結果,並討論了對設計文獻的影響和貢獻。

1 Research approach

To investigate the types of collaborative product design processes and related conditions, we adopted a grounded theory approach in data collection and analysis (Charmaz, 2006; Glaser & Strauss, 2009), and a ‘mosaic method’ that we devised to reconstruct collaborative design processes between indus- trial designers and engineering designers. The grounded theory approach is widely used in social sciences as a systematic methodology to establish theory for less studied areas, while in design research it has been long adopted (e.g. Lee & Cassidy, 2007; Wong, 2010). It uses inductive logic, starting with data collection mostly through in-depth interviews and/or observation. In the cod- ing stage, there are generally two strategies. One is to collect and encode mean- ingful references from the data, and group them into coding categories when research topics are not clearly defined. The other is to use predefined coding categories in line with a particular theme to identify related references when research topics are clearly defined. We used the latter strategy, because the design process has been widely studied. Adopting a similar method, Berends, Reymen, Stultiens, and Peutz (2011) investigated the design processes of five companies. Kleinsmann and Valkenburg (2003) collected stories about collaborative design processes in industry and identified key themes and plots of the collaborative design projects.

1.研究方法

為了研究協作產品設計過程的類型和相關條件,我們在數據收集和分析中採用了紮實的理論方法(Charmaz, 2006; Glaser & Strauss, 2009),以及我們設計用於重新構建協作設計過程的“鑲嵌方法”在工業設計師和工程設計師之間。紮根的理論方法在社會科學中被廣泛用作為研究,較少的領域有建立理論的系統方法,而在設計研究中已被長期採用(e.g. Lee & Cassidy, 2007; Wong, 2010)。它使用歸納邏輯,主要是通過深入的訪談和或觀察開始進行數據收集。在編碼階段,通常有兩種策略。一種是從數據中收集有意義的參考資訊並進行編碼,如果研究主題沒有明確定義,則將它們分為編碼類別。另一種是在明確定義研究主題時,使用符合特定主題的預定義編碼類別來標識相關參考。我們使用了後一種策略,因為對設計過程進行了廣泛的研究。 Berends,Reymen,Stultiens和Peutz(2011)採用了類似的方法,對五家公司的設計過程進行了調查。 Kleinsmann和Valkenburg(2003)收集了有關工業中協同設計過程的事例,並確定了協同設計項目的關鍵主題和過程。

We firstly conducted in-depth interviews with individual designers and collected their stories about design projects. To avoid a possible distortion due to the unreliability or possible inaccuracy of retrospective accounts (Ackroyd & Hughes, 1981), we adopted three criteria for selecting research tar- gets: (1) multiple companies in a similar product domain; (2) multiple partic- ipants from both engineering and industrial design departments; and (3) projects already completed through a whole product development cycle. We set the first criterion to improve the applicability of research results. Under- standing and analysing project contexts improve the applicability of design processes and methods (Gericke & Blessing, 2012). Thus, investigating multi- ple companies with similar project contexts could provide better chances to apply the research results. With the second criterion, the data from multiple informants with different perspectives are complemented by each other to offset any potential bias (Miller, Cardinal, & Glick, 1997). Finally, in retro- spective interviews, the design process can be determined through collecting and analysing the stories of design projects that are already completed through a whole product development cycle (Berends et al., 2011).

我們首先對個別設計師進行了深入採訪,並收集了他們關於設計項目的事例。為避免追溯性帳戶的不可靠性或準確性所造成的可能的失真(Ackroyd&Hughes,1981),我們採用了三個標準來選擇研究目標:(1)相似產品領域中的多家公司; (2)工程和工業設計部門的多個參與者; (3)在整個產品開發週期中已經完成的項目。我們設置了第一個標準來提高研究結果的適用性。對項目環境的理解和分析提高了設計過程和方法的適用性(Gericke&Blessing,2012)。因此,對具有相似項目環境的多家公司進行調查可能會提供更好的機會來應用研究結果。使用第二個標準,來自具有不同觀點的多個受試者的數據將相互補充,以抵消任何潛在的偏見(Miller,Cardinal和Glick,1997)。最後,在回顧性訪談中,可以通過收集和分析整個產品開發週期中已經完成的設計項目的事例來確定設計過程(Berends等,2011)。

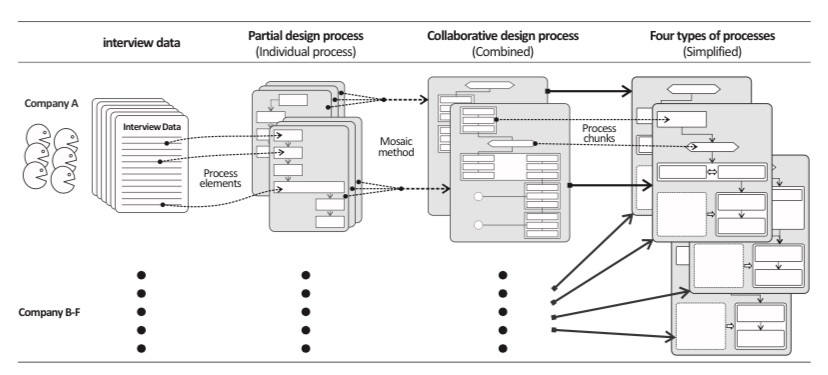

In order to reconstruct product design processes based on transcribed inter- view data, we firstly identified ‘process elements’ and then drew out partial design processes that individual designers practiced. Next, we combined all partial processes in each company into collaborative product design processes using the ‘mosaic method.’ After constructing all detailed collaborative prod- uct design processes, we simplified them with ‘process chunks’ to identify the types of typical design processes. Finally, we visualized them as design process models. Figure 1 shows the research procedure.

為了基於轉錄的訪談數據重建產品設計過程,我們首先確定“過程元素”,然後繪製出各個設計師實踐的部分設計過程。接下來,我們使用“‘mosaic method”將每個公司的所有部分流程組合為協同產品設計流程。在構建了所有詳細的協同產品設計流程之後,我們使用“流程塊”對其進行了簡化,以識別典型設計流程的類型。最後,我們將它們可視化為設計過程模型。圖1顯示了研究過程。

圖1:

Actual design processes and their characteristics in reference to the context can be determined from actual design projects, which may be different from the documented design processes of the companies. Comparing both will provide insight. However, we could not collect them, because they are considered as confidential to the outside. Instead, we asked the interviewees whether their company has a documented standard design process and whether it is different from actual design processes.

可以根據實際設計項目確定實際設計過程及其相對於上下文的特徵,這可能與公司記錄的設計過程不同。比較兩者將提供洞察力。但是,我們無法收集它們,因為它們被視為對外部機密。取而代之的是,我們詢問受訪者他們的公司是否有書面的標准設計流程,以及它是否與實際設計流程不同。

1.1 In-depth interview

1.1.1 Selection of case companies

To increase the applicability, the design process should be understood within the context and environment of a company (Maffin, 1998). As such, we set three criteria by specifying case companies to explore. The three criteria adop- ted are as follows:

1)The companies should produce mid-complex electronic consumer products.

2) They should have independent industrial design and engineering design departments.

3) They should be leading companies in the market producing well-designed high-quality products.

1.1深度訪談

1.1.1案例公司的選擇

為了增加適用性,應該在公司的環境和背景下理解設計過程(Maffin,1998)。因此,我們通過指定案例公司來設置三個標準。所採用的三個標準如下:

(1)公司應生產中等複雜的電子產品。

(2)他們應該有獨立的工業設計和工程設計部門。

(3)他們應該是市場上領先的公司,生產精心設計的高質量產品。

The first criterion enabled the selection of manufacturers with similar in prod- uct domain context wherein both industrial designers and engineering de- signers play important roles. Manufactures producing simple consumer products will require a lesser role from engineering designers. In addition, developing a rocket needs no industrial designer’s role. Ulrich and Eppinger (2012) stated that ‘electromechanical products of modest complexity’ requires equally important roles of industrial designers and engineering de- signers. Based on the classification of engineered consumer products with complexity proposed by Cross (2008), examples of modest complex products are electrical drills and washing machines. Thus, mid-complex electronic con- sumer products refer to everyday consumer electronics goods that are engi- neered products fully integrating electronic and mechanical systems (Vasic & Lazarevic, 2008). Although, the first criterion is satisfied, some companies such as Original Equipment Manufacturers (OEM), or small companies have either one department of industrial design or engineering design, or none. In such cases, they use external design and/or engineering consulting firms. Their collaboration process would be different from that happening between in-house independent industrial design and engineering departments. We in- tended to increase the applicability of research results by exploring cases with similar contexts. Thus, the second criterion was fulfilled. Finally, leading companies producing well-designed and high-quality products could provide reasonable and proper data for investigation, and the findings would be a good source of reference for other companies. Lawson (1994) pointed out that discovering how good design practices take place would be beneficial to understand and prescribe methods more effective. This is the rationale for third criterion.

第一個標準使得能夠選擇在產品領域內具有相似性的製造商,其中工業設計師和工程設計者都扮演著重要的角色。生產簡單消費品的製造商在工程設計師中的作用將減少。此外,開發火箭不需要工業設計師。 Ulrich和Eppinger(2012)指出,“中等複雜度的機電產品”要求工業設計師和工程設計人員重要程度相同。根據Cross(2008)提出的具有復雜性的工程消費品分類,中等複雜產品的例子包括電鑽和洗衣機。因此,中等複雜的電子消費產品指的是日常消費電子產品,它們是完全集成了電子和機械系統的工程產品(Vasi c&Lazarevi c,2008)。儘管滿足第一個條件,但是某些公司(例如原始設備製造商(OEM))或小型公司的工業設計或工程設計部門是一個,或者沒有。在這種情況下,他們會使用外部設計或工程諮詢公司。他們的協同過程將不同於內部獨立工業設計和工程部門之間的協同過程。我們傾向於通過探索具有相似背景的案例來提高研究結果的適用性。因此,滿足了第二個標準。最後,生產精心設計和高質量產品的領先公司可以為調查提供合理和適當的數據,研究結果將為其他公司提供很好的參考。Lawson(1994)指出,發現良好的設計實踐是如何發生的,將有助於理解和製訂更有效的方法。這是第三個標準的理由。

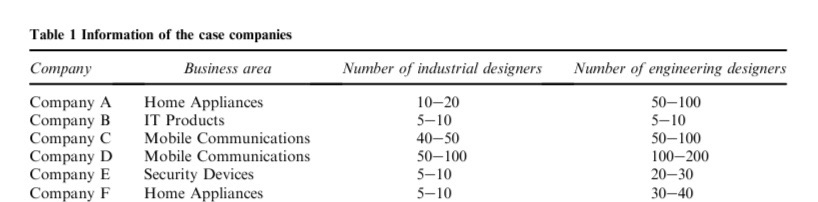

We selected the case companies with the above criteria. We firstly applied first and third criteria to the list of the companies that had won the ‘Korean Good Design Award’ from 2006 to 2010 (About GD, 2011) consecutively. The ‘Korean Good Design Award’ is popular among many market-leading manufacturers in Korea. As a result, we obtained 16 company names. Then, we contacted each company with contact information in the awardee lists, and asked the gatekeepers if they had independent ID and ED departments (second criterion) and if they were willing to participate in the study. Finally, we selected six companies (Table 1).

我們根據以上標準選擇了案例公司。我們首先將第一和第三項標準應用於從2006年至2010年連續獲得“韓國優秀設計獎”的公司(關於GD,2011年)。 “韓國優秀設計獎”在韓國許多市場領先的製造商中很受歡迎。結果,我們獲得了16個公司名稱。然後,我們與獲獎公司列表中的聯繫方式聯繫了每家公司,並詢問主管是否具有獨立的ID和ED部門(第二標準)以及他們是否願意參加研究。最後,我們選擇了六家公司(表1)。

1.1.2 Selection of interviewees

We selected interviewees with purposive and snowball sampling methods (Berg, 1988). The gatekeeper of each company suggested their designers who in turn suggested their co-workers. While doing so, we selected interviewees satisfying the three criteria below:

表1:

1.1.2選擇受訪者

我們選擇了具有目的性和滾雪球式抽樣方法的受訪者(Berg,1988)。每個公司的主管都建議他們的設計師,而後者又建議他們的同事。在這樣做的同時,我們選擇了滿足以下三個條件的受訪者:

(1) More than two years of experience in the company

(2) Engagement in at least one cycle of the product development process

(3) Close collaboration and interaction with counterparts (i.e. industrial de-

signers vs. engineering designers)

(1)兩年以上公司工作經驗

(2)參與至少一個產品開發過程的周期

(3)與同行的緊密合作和互動(即工業設計,

簽名人與工程設計師)

The intended number of interviewees recruited from industrial designer and engineering designer groups in a company was six, with three from each to keep the balance. However we were able to recruit only two engineering de- signers each from Company B and F. In total, 18 industrial designers and 16 engineering designers participated as interviewees. Their working experi- ence ranged from 2.1 to 20 years with an average of 8.9 years.

從一家公司的工業設計師和工程設計師團隊招募的預期受訪者人數為6名,每名受訪者中有3名為了保持平衡。但是,我們只能從B公司和F公司招募兩名工程設計人員。總共有18名工業設計師和16名工程設計師作為受訪者參加。他們的工作經驗從2.1年到20年不等,平均為8.9年。

1.1.3 Interview procedure

We employed a semi-structured in-depth interview method following sug- gested instruction from the literature (Kvale & Brinkmann, 2009; Seidman, 2012). We firstly listed about 20 detailed questions and grouped them into four main themes: 1) personal information, 2) design process, 3) role and expertise, and 4) interaction.We then formulated four key questions:

1.1.3面試程序

根據文獻的建議,我們採用了半結構化深度訪談方法(Kvale&Brinkmann,2009; Seidman,2012)。我們首先列出了約20個詳細問題,並將它們分為四個主要主題:(1)個人信息,(2)設計過程、(3)角色和專業知識以及(4)交互,然後提出了四個關鍵問題:

(1) What is your position and role in the team?

(2) How did the product design process proceed and what happened during

the process?

(3) What tasks did you have in the design process, and what knowledge and

skills you had required to carry out the projects?

(4) How did industrial design(ers) and engineering design(ers) interact with

each other during the design process?

(1)您在團隊中的職位和角色是什麼?

(2)產品設計過程如何進行以及在此過程中發生了什麼

過程?

(3)您在設計過程中擁有哪些任務,以及哪些知識和常識

您執行項目所需的技能?

(4)工業設計和工程設計如何相互作用

在設計過程中互相交流?

The interview started with the first question about interviewees’ roles in their teams and working experiences, followed by the product development processes they experienced and their tasks in such processes. When an inter- viewee hesitated to start talking because of inattention to specify a moment to recall, we provided a detailed context, e.g. ‘Assume that today is the kick- off meeting day for the project you were involved in, and then tell me about what happened.’ This followed the advice for good questioning in an inter- view study; assuming, alternative, ideal, and interpretive questions (Merriam, 1998). To restrict inconsistencies caused by multiple interviewers, one author performed all the interviews (Ahmed, 2007). Moreover, the author had 14 years of industry experience in product development, which limited the possibility of misunderstanding the composed design situation described by interviewees. To avoid bias regarding the interviewer’s experi- ence, this research followed the ‘Epoche’ process in which prejudgment and assumptions about a phenomenon are blocked in order to examine it in the world of participants (Leedy & Ormrod, 2012). Therefore, the interviewer ignored prejudgment on the phenomenon when feeling like judging the in- terviewee’s response. We conducted the interviews in quiet rooms in each company, and audio-recorded all conversations. To help the conversation, and to record supplementary information, we made field notes. Sometimes, interviewees produced drawings on the note to provide a detailed description.

訪談首先是關於受訪者在團隊中的角色和工作經驗的問題,然後是他們經歷的產品開發過程以及在這些過程中的任務。當受訪者由於不願指出要回憶的時刻而猶豫不決時,我們提供了詳細的背景信息,例如:“假設今天是您參與的項目的開工會議日,然後告訴我發生了什麼事。”假設,替代,理想和解釋性問題(Merriam,1998年)。為了限制由多個訪問者引起的不一致,一位作者執行了所有訪問(Ahmed,2007年)。此外,作者在產品開發方面擁有14年的行業經驗,這限制了誤解受訪者描述的綜合設計情況的可能性。為了避免對面試官產生偏見,本研究遵循了“ Epoche”過程,該過程將對現象的判斷和假設封閉,以便在參與者的世界中進行檢查(Leedy&Ormrod,2012年)。因此,面試官在感覺要判斷受訪者的反應時就忽略了對這種現象的判斷。我們在每個公司的會議室中進行了採訪,並對所有對話進行了錄音。為了幫助進行對話並記錄補充信息,我們做了現場說明。有時,受訪者會在便箋上製作圖紙以提供詳細說明。

It is known from experience that 90 min is appropriate for in-depth inter- view time, because informants respond to the interview earnestly within this time and informants’ responses tend to decrease as the time exceeds 90 min (Seidman, 2012). We had a planned interview time of 90 min following the guideline, but we did not control it. We closed interviews when we had enough data regarding the questions by observing that new information from responses is decreased. The ‘voice detection recording function’ in the recorder enabled us to pause recording with a silence for a few seconds and resume when the voice came back. The time of recording ranged from 70 to 100 min per interviewee with an average of 78.5 min for all participants. Therefore, the actual interview time per interviewee should be longer than the recording time. We transcribed all interview data verbatim. As a result, we obtained around 1000 pages of the overall transcription.

從經驗中知道,90分鐘適合進行深度訪談,因為受訪人在這段時間內會認真回答採訪,而受訪人在90分鐘以上時的回應往往會減少(Seidman,2012年)。遵循指南,我們計劃的採訪時間為90分鐘,但我們沒有控制住它。當我們有足夠的關於問題的數據時,我們通過觀察減少了來自答复的新信息,從而結束了訪談。錄音機中的“語音檢測錄音功能”使我們可以無聲地暫停錄音幾秒鐘,並在聲音返回時恢復錄音。每個受訪者的錄音時間從70分鐘到100分鐘不等,所有參與者的平均錄音時間為78.5分鐘。因此,每個受訪者的實際採訪時間應長於錄音時間。我們逐字記錄了所有採訪數據。結果,我們獲得了大約1000頁的全部轉錄。

1.2 Identifying design processes

1.2.1 Identifying design processes that each individual experienced

Although, all transcribed data contained information related to design pro- cesses, they were all intermingled with other contents, including the situation and goal of the project, individuals’ roles, necessary skills and knowledge, con- flicts between actors, perceived images of each other, etc. We firstly formulated a coding framework by reviewing related literature to identify ‘process ele- ments’ that were used for constructing the design process. We confirmed them by perusing Company A’s interview transcription several times. The two perspectives on process modelling, viewing processes as information pro- cessing and state-transition systems provide meaningful clues about coding categories of process elements for the modelling of a process.

1.2確定設計過程

1.2.1確定每個人經歷的設計過程

儘管所有轉錄數據都包含與設計過程有關的信息,但它們都與其他內容混合在一起,包括項目的情況和目標,個人的角色,必要的技能和知識,參與者之間的衝突,每個對象的感知圖像首先,通過回顧相關文獻來確定用於構建設計過程的“過程元素”,從而製定出一個編碼框架。我們通過仔細閱讀A公司的採訪記錄來確認他們。關於過程建模,將過程視為信息處理和狀態轉換系統的兩種觀點為有關過程建模的過程元素的編碼類別提供了有意義的線索。

In the information processing perspective, Browning, Fricke, and Negele (2006) viewed product development and its activities as a process of informa- tion collection, creation, interpretation, transformation, and transfer. Most product development activities require a set of input and produce as outcomes of activities, preliminary outputs, status reports, etc. (Browning et al., 2006). This viewpoint has been supported by an extensive literature on design process and organization (e.g. Burns & Stalker, 1961; Clark, 1991; Hubka & Eder, 2012). Ulrich and Eppinger (2012) described this as information necessary for the final outcome that is injected to transform a current design problem to the next problem to lower uncertainty, and thereby producing output until the final outcome is formed. This is modelled as a process of transforming a functional specification (input) into an artefact specification (output) (Takeda, Veerkamp, & Yoshikawa, 1990; Tomiyama & Yoshikawa, 1986). Browning and Ramasesh (2007) pointed out that process modelling with the perspective of information processing fails to capture full information flow because interaction is poorly understood. They argued the importance of iden- tifying interactions between organizational units, because they incur depen- dency between activities that establish deliverable flow patterns. Conclusively, the basic elements of process modelling in this perspective are summarized as ‘information flow’ with the IPO (InputeProcesseOutput) rep- resentation and ‘interaction’ of organizational units (person, team, company, etc.).

從信息處理的角度來看,Browning,Fricke和Negele(2006)將產品開發及其活動視為信息收集,創建,解釋,轉換和轉移的過程。大多數產品開發活動需要一組輸入,並作為活動的結果,初步輸出,狀態報告等進行生產(Browning等,2006)。這種觀點得到了有關設計過程和組織的大量文獻的支持(例如Burns&Stalker,1961; Clark,1991; Hubka&Eder,2012)。 Ulrich和Eppinger(2012)將其描述為最終結果所必需的信息,該信息被注入以將當前設計問題轉換為下一個問題以降低不確定性,從而產生輸出,直到形成最終結果為止。這被建模為將功能規範(輸入)轉換為製品規範(輸出)的過程(Takeda,Veerkamp和Yoshikawa,1990; Tomiyama和Yoshikawa,1986)。 Browning和Ramasesh(2007)指出,由於對交互的了解不多,從信息處理的角度進行過程建模無法捕獲完整的信息流。他們認為,確定組織單位之間的相互作用的重要性,因為它們會引起建立可交付的流程模式的活動之間的依賴。最終,從這個角度來看,流程建模的基本元素概括為“信息流”與IPO(InputeProcesseOutput)表示以及組織單位(人員,團隊,公司等)的“互動”。

In the state-transition perspective, Reymen (2001) described a design process as the process of moving one state to another by performing a task at each stage and evaluating design activities. This is consistent with stage-gate models, where design activity happens at each stage and design output of the stage is evaluated at design review whereby a decision is made among whether to go to the next stage, repeat the current stage or reject the project (Cagan & Vogel, 2002; Ulrich & Eppinger, 2012). This perspective is advo- cated from most stage-based models (Wynn & Clarkson, 2005). A stage- based model is made up of action that is intended to perform a task, and a decision that is to intended to evaluate the outcomes of performing the task; the completion of which constitutes progression to the next stage (J€ansch & Birkhofer, 2006; Roozenburg & Cross, 1991). Besides this, infor- mation flow accompanying input and output happens when jumping up from one stage to another or linking between sub-processes (Lindemann, 2003; Ogot & Okudan-Kremer, 2004). The engineering design process model proposed by Pahl et al. (2007) demonstrates clear inputs and outcomes of each stage. The input of the first stage is ‘task’ and the outcome is ‘specifica- tion’ that goes into the next stage as an input yet again. In this way, the sequential developmental stages connecting inputs and outcomes are drawn out. Regarding the term ‘task’ and ‘design activity’, Pahl et al. (2007) uses ‘task’ to mean the initial starting point of the project different from ‘task’ executed at each stage. However, these two terms are used similarly to indi- cate performing design work, and thus there is a general consensus about the design process of connecting and proceeding tasks interdependently (Dorst, 2008).

從狀態轉換的角度來看,Reymen(2001)將設計過程描述為通過在每個階段執行任務並評估設計活動將狀態從一種狀態轉移到另一種狀態的過程。這與階段模型一致,在階段模型中,每個階段都會進行設計活動,並在設計評審中評估階段的設計輸出,從而決定是否進行下一階段,重複當前階段或拒絕項目。(Cagan&Vogel,2002; Ulrich&Eppinger,2012)。大多數基於階段的模型都提倡這種觀點(Wynn&Clarkson,2005)。基於階段的模型由旨在執行任務的動作和旨在評估執行任務的結果的決策組成;這項工作的完成構成了下一階段的發展(J€ansch&Birkhofer,2006; Roozenburg&Cross,1991)。除此之外,當從一個階段跳到另一個階段或在子過程之間鏈接時,伴隨輸入和輸出的信息流就會發生(Lindemann,2003; Ogot和Okudan-Kremer,2004)。 Pahl等人提出的工程設計過程模型。 (2007)證明了每個階段的明確投入和成果。第一階段的輸入為“任務”,結果為“規範”,該輸入再次進入下一階段。這樣,繪製出了將輸入和結果連接起來的順序發展階段。關於“任務”和“設計活動”,Pahl等人。 (2007)使用“任務”來表示項目的初始起點,不同於在每個階段執行的“任務”。但是,這兩個術語的用法類似,用以表示執行設計工作,因此,人們對相互連接和處理任務的設計過程達成了普遍共識(Dorst,2008年)。

Taken into the state-transition perspective, there are two activities: performing task and evaluating outcomes. Mostly, evaluation happens within a relatively short period of time to decide between ‘go forward, repeat, or drop.’ Hence, we named these kinds of activities (evaluation, design review, gate check, deci- sion-making) as ‘event.’ At this juncture, we have two coding categories; ‘task’ and ‘event.’ In conclusion, we can model a design process with four cod- ing categories; ‘task,’ ‘event,’ ‘information flow,’ and ‘interaction,’ and can be represented with the connection of stages. At this point, a stage of a design process can be represented with ‘inputetask (design activity)eevent (deci- sion-making)eoutput.’ The followings describe how to encode process ele- ments with the above four coding categories.

從狀態轉換的角度來看,有兩個活動:執行任務和評估結果。通常,評估是在相對較短的時間內進行的,以便在“前進,重複或下降”之間做出決定。因此,我們將這些活動(評估,設計審查,門禁檢查,決策)稱為“事件”。目前,我們有兩個編碼類別;總而言之,我們可以用四個編碼類別對設計過程進行建模。“任務”,“事件”,“信息流”和“互動”,並且可以通過階段的關聯來表示。此時,設計過程的一個階段可以用“輸入任務(設計活動)事件(決策制定)輸出”來表示。以下內容描述如何使用以上四種編碼類別對過程要素進行編碼。

Task: Clear tasks that designers perform such as ‘idea sketches,’ ‘3D model- ling’, etc. A respondent said; ‘Yes, I do rough sketches with a ballpoint pen to express my idea. Little colouring on it or scan it to retouch on Photoshop.’ We encoded this into a task category with the label ‘idea sketch.’

任務:清除設計人員執行的任務,例如“想法草圖”,“ 3D建模”等。 ‘是的,我用圓珠筆粗略地表達了我的想法。它上的顏色很少,或者掃描後可以在Photoshop上進行修飾。”我們將其編碼為帶有“想法草圖”標籤的任務類別。

Event: After a particular task, an event (decision-making) proceeds, leading to the next action. A respondent said; ‘We go to the mock-up company to make prototypes, and bring all two or three prototypes. A mock-up evaluation meeting is held with them. . (omit) . the engineers listen to the boss’s crit- icism. The boss states this is this and that is that, then, if engineers have different ideas, they provide opinions .. (omit) . finally the one is selected. We encoded this with the label, ‘mock-up evaluation meeting,’ in the event category.

事件:完成特定任務後,將進行一個事件(決策),從而導致下一個動作。一位受訪者說; ‘我們去樣板公司製作原型,並帶走所有兩個或三個原型。與他們舉行了一次模擬評估會議 。工程師們聽老闆的批評。老闆說就是這樣,那就是,如果工程師有不同的想法,他們會提供意見..。最後一個被選中。我們在活動類別中使用“模擬評估會議”標籤對此進行了編碼。

Information Flow: Information flow is generated when a task or an event happens. It is always accompanied by input and output. A respondent said; ‘In fact, we work based on specifications received from engineering de- signers. We don’t start our work until something arrives.’ This describes that the industrial designers received ‘specification data’ from engineering designers as an input, with which they started their work. We encoded this ‘specification data from ED to ID.’ Another excerpt is; ‘. when one is selected, we pass the 3D Data of the mock-up to the engineering depart- ment. . (omit) . we send ‘STEP’ files, then they use ‘UG’ to start design.’ This describes that they sent 3D CAD data as the output of their design ac- tivity to engineering designers, which become an input for the following en- gineering design activity. We encoded this ‘3D CAD data from ID to ED.’

資訊交流:當任務或事件發生時會生成信息流。它總是伴隨著輸入和輸出。一位受訪者說; ‘事實上,我們根據工程設計人員提供的規范進行工作。我們要等到事情來臨時才開始工作。”這表示工業設計師從工程設計師那裡收到了輸入的“規格數據”作為他們開始工作的依據。我們對“從ED到ID的規範數據”進行了編碼。 ‘。選擇一個後,我們會將模型的3D數據傳遞到工程部門。我們發送“ STEP”文件,然後他們使用“ UG”開始設計。”這說明他們向工程設計人員發送了3D CAD數據作為其設計活動的輸出,這些輸入成為後續工程設計的輸入。活動。我們對“從ID到ED的3D CAD數據”進行了編碼。

Interaction: When a task or event takes place, the two groups frequently interact. For example, while industrial designers checked whether the inside space could be modified, engineering designers advised them by providing related information. In such cases, intensive interaction happens and the en- gineering designer serves as an ‘advisor.’ A response is the case; ‘They explain ‘this should be placed here and that should be placed there.’ Then, we modify the size and position and ask them again whether the 2-mm gap can be reduced. If they say ‘Yes,’ we flatten one part against another.’ We en- coded this as ‘advisor role of ED to ID.

交互:發生任務或事件時,兩組經常交互。例如,當工業設計師檢查是否可以修改內部空間時,工程設計師通過提供相關信息為他們提供建議。在這種情況下,會發生激烈的互動,而工程設計人員會充當“顧問”的角色。 ‘他們解釋說‘應該放在這裡,應該放在那裡。’然後,我們修改尺寸和位置,然後再次詢問他們是否可以減小2毫米的間隙。如果他們說“是”,我們會將一個部分與另一個部分拼合。”我們將其編碼為“ ED到ID的顧問角色”。

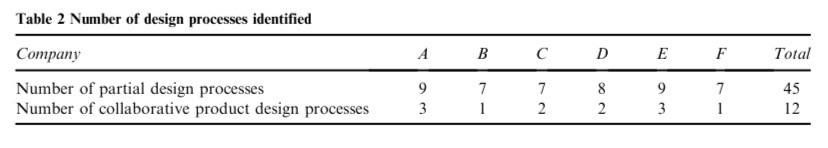

We identified process elements from every piece of transcribed interview data. We labelled them with the participant’s own word as far as possible. We used the field notes as a supplementary data source. While doing so, we arranged and connected the encoded elements in a flowchart format chronologically to construct partial design processes. This method is widely adopted to visu- alize process models in industry (Vergidis, Tiwari, & Majeed, 2008). We also determined the project types and goals involved in the design processes from the interview data. Two researchers executed the whole procedures. One researcher firstly constructed partial design processes, and the other researcher examined them by inspecting the interview data. As a result, we obtained 45 partial design processes with 7-9 from each company (see the second row in Table 2).

我們從每個轉錄的訪談數據中識別出流程要素。我們盡可能用參與者自己的話語標記他們。我們將現場說明用作補充數據源。在此過程中,我們按時間順序排列並連接了編碼元素,以構建部分設計過程。該方法被廣泛採用以可視化行業中的過程模型(Vergidis,Tiwari和&Majeed,2008年)。我們還根據訪談數據確定了設計過程中涉及的項目類型和目標。兩名研究人員執行了整個程序。一位研究人員首先構建了部分設計流程,另一位研究人員通過檢查訪談數據對其進行了檢查。結果,我們從每個公司用7-9獲得了45個局部設計過程(請參見表2中的第二行)。

表2:

1.2.2 Identifying collaborative product design processes

The next stage was to combine each company’s design processes into collabora- tive design processes via a ‘mosaic method.’ We firstly collected partial design processes from a particular project in a company. This was easily done because designers in a company described shared experiences in the same projects, whereby the individual partial design processes overlapped and supplemented each other. After that, we combined the partial processes by comparing and merging process elements. The partial processes extracted from industrial de- signers’ interview data provided rich information on industrial design activities, including interactive behaviours with engineering designers but less information on pure engineering design activities. This was also the case for engineering design. We merged partial processes from industrial designers in a company to rebuild the design processes around industrial design activities. At the same time, we used the information provided by engineering designers to supplement and strengthen the design activity flows from the engineering design side. We rebuilt the design processes around engineering design activities in the same way. We finally merged the two design processes into one collaborative product design process. In the mosaic method, combining the crosschecked partial pro- cesses is beneficial for higher reliability and commonality. This significantly reduced the likelihood of constructing a process with incomplete information by offsetting each other’s information. Thus, the ‘mosaic method’ decreased the possibility of constructing an inaccurate process.

1.2.2確定協作產品設計流程

下一步是通過“mosaic method”將每個公司的設計過程結合到協作設計過程中。我們首先從公司的特定項目中收集了部分設計過程。之所以容易做到這一點,是因為公司的設計師描述了同一項目中的共享經驗,因此各個局部設計過程相互重疊並相互補充。之後,我們通過比較和合併過程元素來合併部分過程。從工業設計者的訪談數據中提取的部分過程提供了有關工業設計活動的豐富信息,包括與工程設計師的互動行為,但有關純工程設計活動的信息較少。工程設計也是如此。我們將公司中工業設計師的部分流程合併在一起,以圍繞工業設計活動重建設計流程。同時,我們利用工程設計師提供的信息來補充和加強工程設計方面的設計活動流程。我們以相同的方式圍繞工程設計活動重建了設計流程。我們最終將這兩個設計過程合併為一個協作產品設計過程。在鑲嵌方法中,結合交叉檢查的局部過程有利於提高可靠性和通用性。通過抵消彼此的信息,這大大降低了構建信息不完整的流程的可能性。因此,“mosaic method”降低了構建不准確流程的可能性。

While comparing partial design processes, we found the product planning team was involved in some design process elements. Thus, we included its role. This implies that the product planning team plays a certain role in collab- orative design projects of industrial design and engineering design. We also standardized some terms that indicated the same tasks or events. But, they were encoded differently because interviewees had used them slightly differ- ently from each other. For example, we found that a meeting was encoded as ‘Product Planning Meeting’ in one partial design process and ‘Product Development Meeting’ in another. Thus, we unified them as ‘Product Planning Meeting.’ Some also called the industrial design outcome differently such as ‘mock-up,’ ‘design mock-up,’ or ‘mock-up fabrication.’ We unified them as ‘design mock-up.’ We also standardized ‘mock-up evaluation event’ and ‘mock-up selection’ as ‘mock-up evaluation event.’ This work was done by cross- checking interview data in each company while evaluating the meaning and context of the specific terms. Actually, designers seemed to understand each company’s documented design process where standard terminology was defined, but were not particularly conscious of it. It seemed that they ignored the standardized process because the market situation was pushing them to move fast. Language difference is also a possible cause of the term difference. In the product design area, native words and borrowed words are mixed in use in Korea. For example, we use both borrowed words and native words indi- cating ‘design’ in English. Besides, cultural and locational differences of the two teams are likely to cause term difference. Except for Company F, the two departments were located in different physical spaces, at least on different floors.

在比較部分設計過程時,我們發現產品計劃團隊參與了一些設計過程元素。因此,我們包括了它的作用。這意味著產品規劃團隊在工業設計和工程設計的協同設計項目中扮演著一定的角色。我們還標準化了一些表示相同任務或事件的術語。但是,它們的編碼方式不同,因為受訪者使用它們的方式略有不同。例如:我們發現一個會議在一個局部設計過程中被編碼為“產品計劃會議”,而在另一個局部設計過程中被編碼為“產品開發會議”。因此,我們將它們統一為“產品計劃會議”。也有人將工業設計結果稱為“模型”,“設計模型”或“模型製造”。我們將它們統一為“設計模型”。我們還將“模擬評估事件”和“模擬選擇”標準化為“模擬評估事件”。這項工作是通過對每個公司的面試數據進行交叉檢查,同時評估了評估的意義和環境來完成的。具體條款。實際上,設計師似乎了解每家公司定義了標準術語的文件化設計過程,但並沒有特別意識到這一點。他們似乎忽略了標準化流程,因為市場形勢迫使他們迅速採取行動。語言差異也是造成術語差異的可能原因。在產品設計領域,韓國語中的母語和借來的單詞混合使用。例如,我們同時使用借用詞和用英語表示“設計”的母語。此外,兩支球隊的文化和位置上的差異很可能會導致期限上的差異。除F公司外,這兩個部門分別位於不同的物理空間,至少位於不同的樓層。

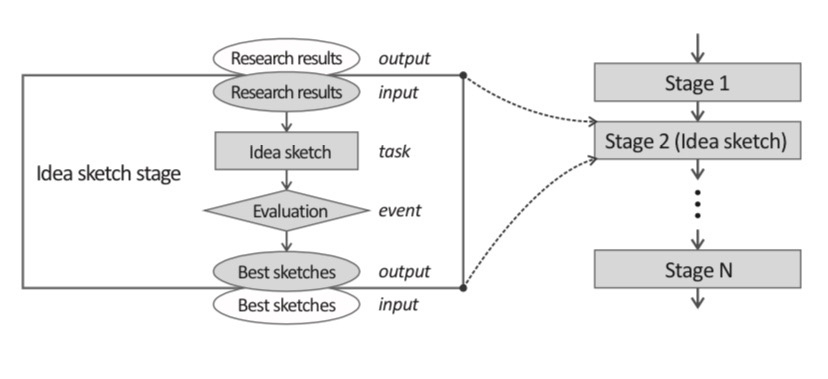

Finally, we defined stages in a design process by merging stage elements (input, task, event, and output) into a box, and named them with related tasks (See Figure 2). For example, industrial designers start drawing various idea sketches based on research results of the previous stage. Then, they select a few best sketches through evaluation. According to the selection result, they decide to go to the next stage or repeat the current one. Therefore, the ‘idea sketch’ stage is composed of ‘research results (input),’ ‘idea sketch (task),’ ‘eval- uation (event),’ and ‘best sketches (output).’

最後,我們通過將階段元素(輸入,任務,事件和輸出)合併到一個框中並在其中將它們與相關任務進行命名,來定義設計過程中的階段(參見圖2)。例如,工業設計師開始根據前一階段的研究結果繪製各種構想草圖。然後,他們通過評估選擇一些最佳草圖。根據選擇的結果,他們決定進入下一階段或重複當前階段。因此,“想法草圖”階段由“研究結果(輸入),”想法草圖(任務),“評估(事件)”和“最佳草圖(輸出)”組成

圖2:

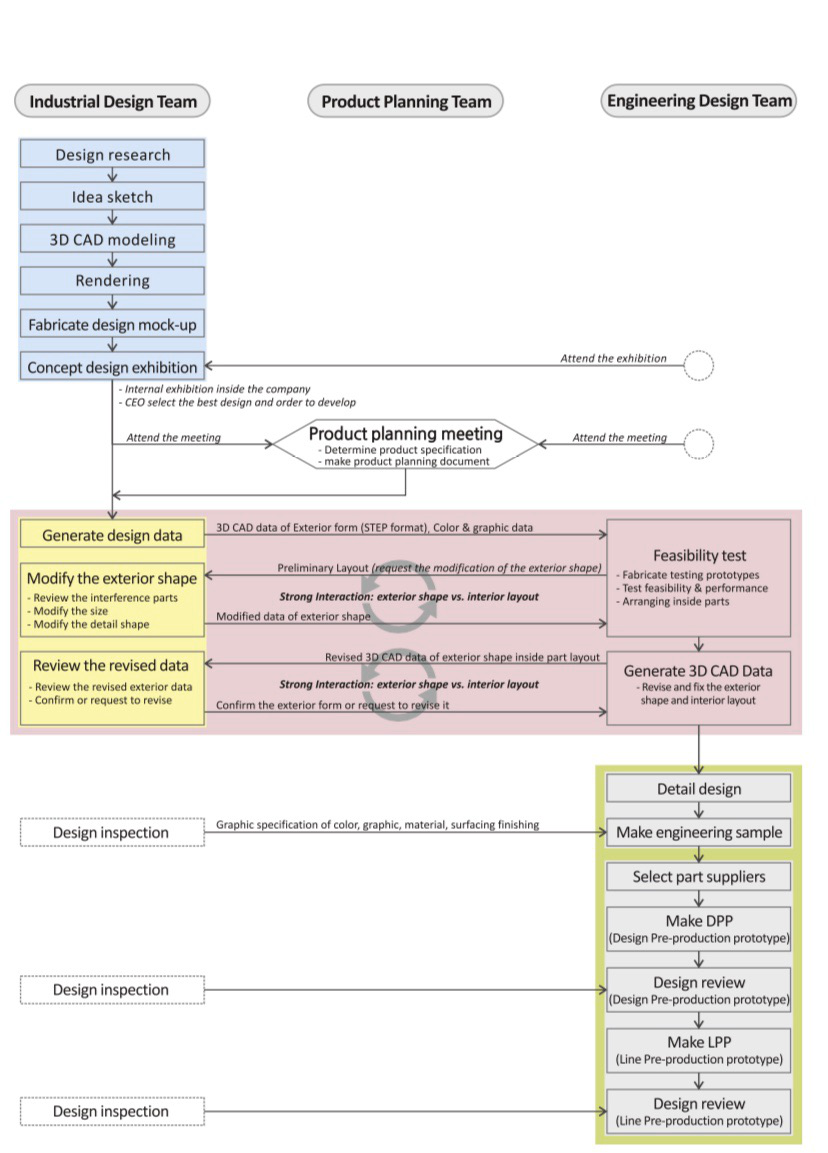

As a result, we obtained 12 collaborative product design processes from all companies; one to three from each company (see the third row in Table 2). We sent them to the informants of each company to check our interpreta- tion of their processes. There were minor changes made in this process. Figure 3 shows a collaborative product design process of Company A. It shows two parallel processes on either side: an industrial design process on the left and an engineering design process on the right, with the interac- tion between the two illustrated in the middle. A ‘product planning meeting’ in the middle is an event hosted by the ‘product planning team,’ where they make a decision, if they move forward to commercialize the concept or re- jected it. The text boxes are stages composed of input-task-event-output. Text boxes with dotted lines are not stages. They do not have all four- stage elements. For example, ‘inspection’ is a kind of decision. There is no input and output. The vertical arrows indicate the progress of the flow. It also shows the direction of information flow, where the output of the former stage becomes the input of the next stage. The horizontal arrows show the direction of ‘information flow’ or ‘interaction.’ The circular arrows represent repeated and strong interaction within the phases. Colours in Figures 3 and 5 show their connectivity. These are later categorized as phases and ex- plained in the next section.

結果,我們從所有公司獲得了12個協同產品設計流程;每個公司一到三個(請參閱表2中的第三行)。我們將它們發送給每個公司的受訪者,以檢查我們對其流程的解釋。在此過程中進行了較小的更改。圖3顯示了公司A的協作產品設計過程。它在兩側顯示了兩個並行的過程:左側是工業設計過程,右側是工程設計過程,中間示出了兩者之間的相互作用。中間的“產品規劃會議”是由“產品規劃小組”主持的活動,由他們決定是否繼續將概念商業化或拒絕。文本框是由輸入任務事件輸出組成的階段。帶有虛線的文本框不是階段。它們沒有所有四個階段的元素。例如,“檢查”是一種決定。沒有輸入和輸出。垂直箭頭指示流程的進度。它還顯示了信息流的方向,前一級的輸出變成了下一級的輸入。水平箭頭表示“信息流”或“交互”的方向。圓形箭頭表示各階段中反复且強烈的交互。圖3和5中的顏色顯示了它們的連通性。稍後將這些分類為階段,並在下一部分中進行說明。

1.2.3 Simplifying the processes

Once we formulated each company’s collaborative product design processes, we categorized them to determine the types, purposes, and conditions of them. Yet, as each company’s processes include detailed design actions and in- formation, it is not easy to compare them directly between companies. Thus, we simplified each company’s design processes with the concept of ‘process chunks’ to aid their comparability, while maintaining the essential characteristics.

1.2.3簡化流程

一旦我們制定了每個公司的協作產品設計流程,我們就將它們分類以確定它們的類型,目的和條件。但是,由於每個公司的流程都包含詳細的設計動作和信息,因此直接在公司之間進行比較並不容易。因此,我們通過“流程塊”的概念簡化了每個公司的設計流程,以幫助它們保持可比性,同時又保持基本特徵。

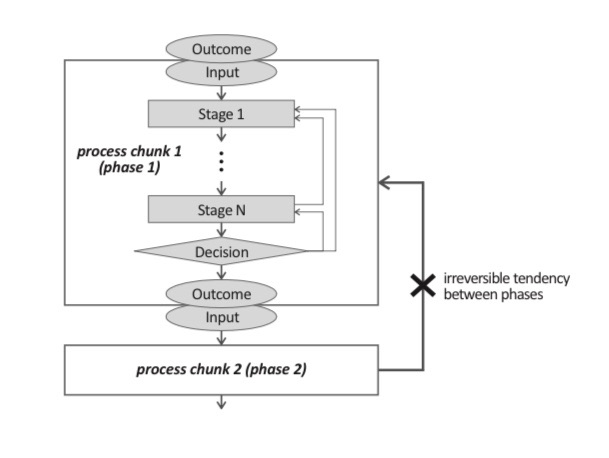

We found that there was a pattern in a group of small sequential stages. There is a major job completed going through all sequential stages. After completing it, a clear new phase starts with another job. We defined those small stages as ‘process chunks.’ It is characterized by initial input, internal iteration, decision- making, final outcome, and irreversible tendency (Figure 4). The internal process in a process chunk starts with the initial input and runs across small stages inside. Iteration or feedback can happen among small stages inside the chunk. Finally, they make the final decision about the final outcomes. This is a milestone indicating that the phase is to jump over to the next phase. For example, in Figure 3 in the blue block, the major job in this chunk is to develop a design concept executing six small stages. When they are in the rendering stage, they can go back in the idea sketch stage if the rendering out- comes are not satisfied at the rendering evaluation event. At the last stage, a design mock-up as the outcome is confirmed by a top management, and then it jumps to ‘product planning meeting.’

我們發現在一組小的連續階段中存在一種模式。所有主要階段都完成了一項主要工作。完成後,一個清晰的新階段從另一個工作開始。我們將這些小階段定義為“流程塊”。其特徵在於初始輸入,內部迭代,決策,最終結果和不可逆趨勢(圖4)。流程塊中的內部流程從初始輸入開始,並在內部的各個小階段中運行。迭代或反饋可能在塊內的各個小階段之間發生。最後,他們對最終結果做出最終決定。這是一個里程碑,指示該階段將跳到下一階段。例如,在圖3的藍色方框中,此塊的主要工作是開發執行六個小階段的設計概念。當他們處於渲染階段時,如果在渲染評估事件中不滿意渲染結果,則可以返回到構思草圖階段。在最後階段,設計樣機作為結果由高層管理人員確認,然後跳至“產品計劃會議”。

The process flow between the two process chunks has a little chance to be reversed after the previous outcome goes into the input of the next chunk. The cross-teams generally make the final design, which is approved by the top manager at each chunk. To go back to the previous chunk means that it could not meet the timeline to the market. Thus, there should be a top man- agement’s decision on the issue. Based on interview data, they would rather drop the project than go back to the previous phase. Iteration and feedback among phases are characterized in most stage-based models (Wynn & Clarkson, 2005). Considering a process chunk or two parallel chunks as a phase in this study, however, the reverse iteration or feedback between phases seldom happens in actual situations. It happens between stages inside a chunk. Thus, it seems that the abandonment of a project is almost impossible between stages but possible between phases.

在前一個結果進入下一個過程塊的輸入之後,兩個過程塊之間的過程流幾乎沒有機會被逆轉。跨團隊通常進行最終設計,並由高層經理在每個工作組中批准。回到上一個區塊意味著它無法滿足市場時間表。因此,應該由最高管理層對此事做出決定。根據訪談數據,他們寧願放棄該項目,也不願返回上一個階段。在大多數基於階段的模型中都對階段之間的迭代和反饋進行了描述(Wynn&Clarkson,2005)。但是,在本研究中,將一個過程塊或兩個並行塊視為一個階段,因此在實際情況中很少會發生階段之間的反向迭代或反饋。它發生在一個塊中的各個階段之間。因此,似乎在階段之間幾乎不可能放棄項目,但是在階段之間可以放棄。

We named the process chunks by their main jobs. While naming the chunks, we found that the term ‘concept design’ is used differently by engineering design and industrial design. Concept design in engineering design is about technical concepts related to how a product works by developing broad solu- tions to the working structure and functions (Haik & Shahin, 2010; Kroll, Condoor, & Jansson, 2001; Ullman, 2009). However, industrial designers decide the direction of product style and interaction at the concept design phase, which is represented with concept keywords, mood boards, idea sketches and user scenarios (Press & Cooper, 2003; Tovey & Harris, 1999; Vredenburg, Isensee, Righi, & Design, 2001). Thus, we marked the concept

design activity of industrial designers as ‘Concept Design-I’ and that of engi- neering designers as ‘Concept Design-E.’

我們通過其主要工作來命名流程塊。在命名這些過程塊時,我們發現“概念設計”一詞在工程設計和工業設計中的用法有所不同。工程設計中的概念設計是與技術概念有關的技術概念,該技術概念通過開發對工作結構和功能的廣泛解決方案來與產品的工作方式相關(Haik&Shahin,2010; Kroll,Condoor,&Jansson,2001; Ullman,2009)。但是,工業設計師在概念設計階段決定產品樣式和交互作用的方向,這由概念關鍵字,情緒板,想法草圖和用戶場景來表示(Press&Cooper,2003; Tovey&Harris,1999;Vredenburg,Isensee, Righi和&Design,2001年)。因此,我們標記了這個概念工業設計師的設計活動稱為“ Concept Design-I”,而工程設計師的設計活動稱為“ Concept Design-E”。

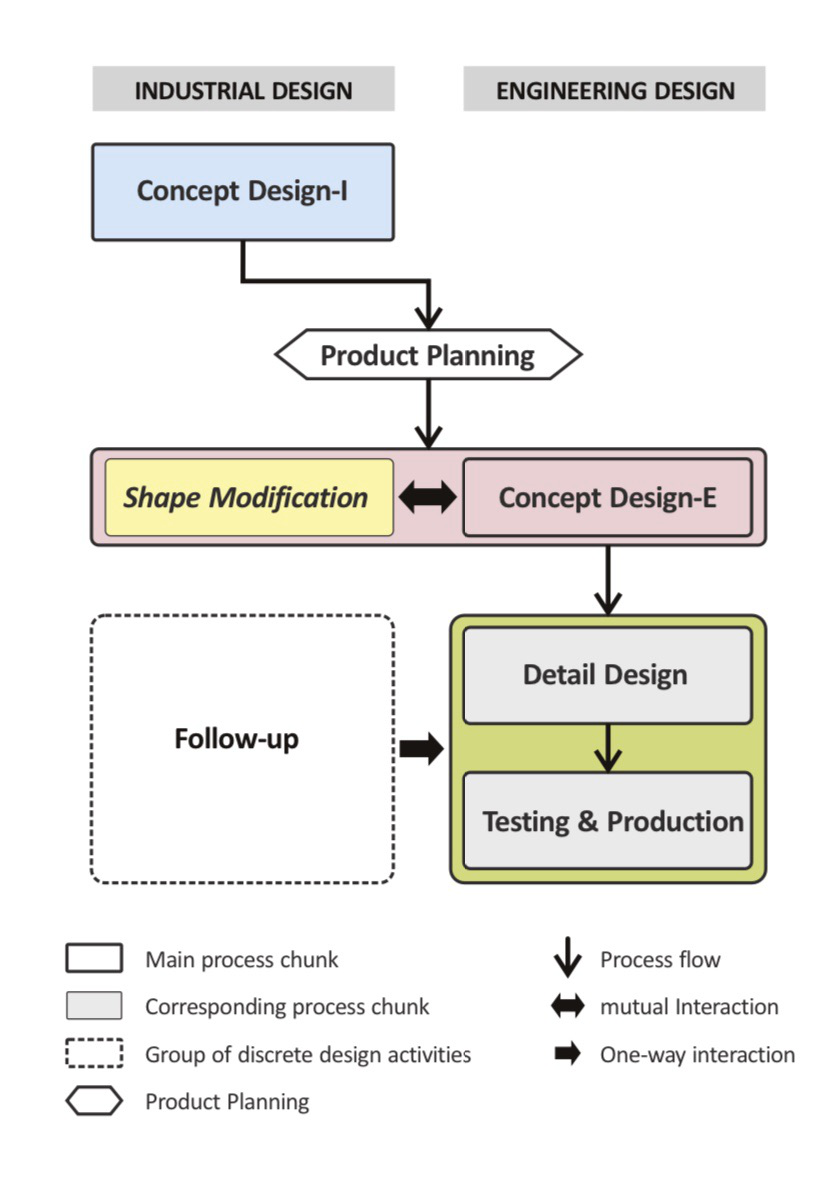

Figure 5 is the simplified version of Figure 3. The coloured boxes in Figure 3 are simplified with the same coloured blocks in Figure 5. The blue block in Figure 3 becomes ‘Concept Design-I.’ ‘Product Planning Meeting’ in Figure 3 is defined as ‘Product Planning’ and visualized with an elongated hexagon. It is determined as a single phase as it is a separated and distinctive design activity. Inside the red block, there are two parallel process chunks; ‘Concept Design-E’ on right side (the small red box), that is the ‘main process chunk,’ and ‘Shape Modification’ on the left-hand side (yellow), a ‘correspond- ing chunk.’ These two chunks are not deemed separate phases because they are coupled with the start to the end inside the big red block. As such, interaction between the two designer groups is strong. To differentiate two parallel chunks, we represented the main chunk with thick solid lines and the corre- sponding chunk with light solid lines. In the green blocks, as there was a little difference in the design activities between all 12 processes, we combined the two sequential process chunks of detail design and testing and production into one. As such, we treated them as a single phase in this study. When the design process in the green block proceeds, industrial designers react from time to time based on engineering designers’ requests or their own purpose for design inspection. They usually called these activities as ‘Follow-up’ differ- entiating from their major tasks. These kinds of activities apparently existed but do not belong to a process chunk. They are discrete process elements as shown in Figure 3, and thus represented with dotted lines. To help visual un- derstanding, solid arrows, a double directional wide arrow, and a single direc- tional wide arrow represent process flow, mutual interaction, and one-way interaction respectively.

圖5是圖3的簡化版本。圖3中的彩色框使用圖5中的相同彩色框進行了簡化。圖3中的藍色框變為“概念設計-I”。圖3中的“產品計劃會議”為定義為“產品計劃”,並以細長的六邊形可視化。由於它是一個單獨且獨特的設計活動,因此被確定為單個階段。在紅色塊內部,有兩個並行的處理塊;右邊的“ Concept Design-E”(紅色的小方框)是“主流程塊”,左邊的是“形狀修改”(黃色),是“對應的塊”。塊並不能視為單獨的階段,因為它們與大紅色塊內的開始到結束相結合。這樣,兩個設計師團隊之間的互動就很強。為了區分兩個平行的塊,我們用粗實線表示主塊,並用淺實線表示相應的塊。在綠色塊中,由於所有12個流程之間的設計活動都沒有什麼區別,因此我們將詳細設計,測試和生產的兩個順序流程塊合併為一個。因此,在本研究中我們將它們視為一個階段。當綠色方框中的設計過程繼續進行時,工業設計師會根據工程設計師的要求或他們自己的設計檢查目的不時做出反應。他們通常將這些活動稱為“後續活動”,與主要任務有所不同。這些活動顯然存在,但不屬於流程塊。它們是如圖3所示的離散過程元素,因此用虛線表示。為了幫助視覺理解,實心箭頭,雙向寬箭頭和單個方向寬箭頭分別表示過程流,相互交互和單向交互。

圖3:

圖4:

圖5:

1.2.4 Determining types of collaborative design processes

We compared and categorized the 12 simplified collaborative product design processes based on similarities in their process structure, input and outcomes of process chunks and phases, and interaction between industrial designers and engineering designers. We first compared every process chunk and phase with corresponding process chunks and phases from the other 11 processes in terms of structure. Then, we compared inputs and outcomes of every corre- sponding phase across the 12 processes. For example, the ‘Concept Design-I’ phase in Figure 5 has no input, but produces ‘design mock-up’ as an output. Some ‘Concept Design-I’ phases in other processes started with the receipt of the preliminary layout from the engineering design teams. Therefore, examining the types of inputs and outcomes of phases give a clue to determine how the over- all process flows. Finally, we evaluated the interaction between industrial de- signers and engineering designers within a phase. There is no interaction between the two groups in the blue block. However, in the red blocks, there are strong interactions between them. As a result, we grouped the 12 collabora- tive product design processes into four types of representative processes.

1.2.4確定協作設計過程的類型

我們根據流程結構,流程塊和階段的輸入和結果的相似性以及工業設計師和工程設計師之間的交互性,對12個簡化的協同產品設計流程進行了比較和分類。我們首先將每個流程塊和階段與其他11個流程的相應流程塊和階段進行結構比較。然後,我們比較了12個流程中每個相應階段的投入和結果。例如,圖5中的“概念設計-I”階段沒有輸入,但是產生了“設計模型”作為輸出。其他流程中的某些“概念設計-I”階段始於工程設計團隊的初步佈局設計。因此,檢查階段的輸入和結果的類型為確定總體流程如何進行提供了線索。最後,我們評估了一個階段中工業設計人員與工程設計人員之間的互動。藍色方框中的兩個組之間沒有交互。但是,在紅色塊中,它們之間存在強大的交互作用。結果,我們將12個協作產品設計過程分為四種代表性過程。

2 Types of collaborative product design processes

We named the four types of collaborative product design processes based on their characteristics. They are Type 1: ID-led Concept-driven Process; Type 2: ID-led Combined Outside-inside Process; Type 3: ED-led Inside-first Process; and Type 4: ID&ED Synergetic Process, and differences between them are mostly found in the early phases of the processes where design concepts and preliminary layouts are developed. There is a little difference after the detail design phase where the engineering designers’ tasks dominate. It is rather standardized. This indicated that the types of collaborative product design processes are determined by the approaches adopted before the detail design phase.

2.協作產品設計過程的類型

我們根據協作產品設計過程的特徵來命名四種類型。它們是類型1:由ID主導的概念驅動過程;類型2:由ID領導的內外聯合流程;類型3:ED主導的內部流程;和類型4:ID&ED協同過程,它們之間的差異主要存在於開發設計概念和初步佈局的過程的早期階段。在詳細設計階段之後,工程設計師的任務占主導地位,這之間存在一些差異。它相當標準化。這表明協作產品設計過程的類型由詳細設計階段之前採用的方法確定。

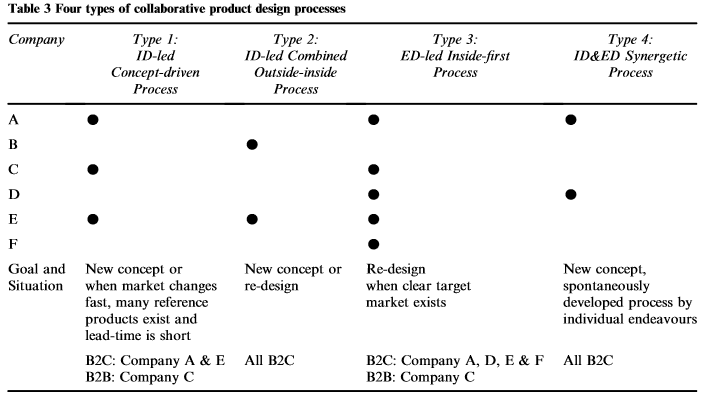

The companies adopted one to three types of design processes according to their goals and situations (See Table 3). Type 1 and 4 were used only for new designs except Company C which adopted Type 1 when the market requested a new styling within a short period of time. This happened when they had many reference products and lead-time was short. Type 2 was used for both new design and redesign. Interestingly, Type 3 was utilized only for redesign. Most processes were used for B2C except in Company C, ‘a mobile communication product manufacturer,’ which releases its products to the market through service providers. Considering that, Company C used Type 1 in a different situation from Company A and E, the business type (B2B or B2C) would affect the choice of design processes.

兩家公司根據其目標和情況採用了一到三種類型的設計流程(請參見表3)。類型1和4僅用於新設計,但C公司在市場要求在短時間內進行新樣式時採用了類型1。當他們有很多參考產品並且交貨時間很短時,就會發生這種情況。 Type 2用於新設計和重新設計。有趣的是,類型3僅用於重新設計。除公司C(“移動通信產品製造商”)通過服務提供商向市場發布其產品外,大多數流程都用於B2C。考慮到C公司在與A公司和E公司不同的情況下使用Type 1,業務類型(B2B或B2C)將影響設計流程的選擇。

Regarding the difference between actual design process and documented process, most of them responded that they have documented standard design processes in all companies, but they do not follow at all. This is supported by the finding by Maffin (1998) that designers develop their own approaches in accordance with product development context. It seemed that the documented process defined standardized task flows and stages, tasks and roles of each department, and project time according to project types. However, they were always pushed to shorten the actual project time. This kind of management pressure likely causes them not to follow the documented process.

關於實際設計過程和書面過程之間的區別,大多數人回答說他們已經記錄了所有公司的標准設計過程,但根本沒有遵循。 Ma ffi n(1998)的發現支持了這一點,即設計師根據產品開發環境開發了自己的方法。似乎已記錄在案件的流程根據項目類型定義了標準化的任務流和階段,每個部門的任務和角色以及項目時間。但是,他們總是被迫縮短實際項目時間。這種管理壓力很可能導致他們不遵循記錄的流程。 表3:

By comparing the frequency of use of each type of process, we found that Type 3 was the most frequently used, whereas Type 4 was the least. Type 2 was used more frequently than Type 1. Except in the case of Company B, Type 3 is most similar to that most interviewees described as the company standard. Considering the argument that redesign occurs more frequently than new design (Roozenburg & Eekels, 1995) and successful radical innovation happens perhaps once every 5e10 years (Norman & Verganti, 2014), this is a reasonable finding. As Type 4 is spontaneously initiated by individuals, and is not a set of official, standard procedures, the case is rare. The detailed characteristics of each type of design process along with related contexts are described in the following sections.

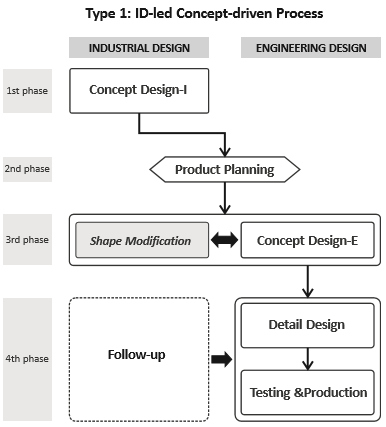

通過比較每種類型過程的使用頻率,我們發現類型3是最常用的,而類型4是最少的。使用類型2的頻率比使用類型1的頻率更高。除了公司B的情況外,類型3與大多數受訪者所說的公司標準最為相似。考慮到重新設計比新設計更頻繁發生的論點(Roozenburg&Eekels,1995),成功的徹底創新可能每5-10年發生一次(Norman&Verganti,2014),這是一個合理的發現。由於類型4是個人自發發起的,並且不是一套官方的標準程序,因此這種情況很少見。以下各節介紹了每種類型的設計過程的詳細特徵以及相關的上下文。2.1 Type 1: ID-led Concept-driven ProcessIndustrial designers play a dominant role in deciding the direction of product development in the initial stage in Type 1. It has four phases in accordance with the process chunks, as shown in Figure 6.2.1類型1:由ID主導的概念驅動的過程工業設計人員在決定類型1初始階段的產品開發方向方面起著主導作用。根據過程塊,它分為四個階段,如圖6所示。

1st phase (Concept Design-I): Industrial designers independently develop the concept of a product without any interference from other departments. They focus mostly on the aspects relevant to the aesthetic exterior and user experience. They rarely consider the internal parts, which gives a lot of freedom to them. They produce 3D CAD data for the exterior and high-quality rendered images to test the concept. Once the exterior form is finally decided, they produce a ‘design mock-up,’ a non-functional prototype, to verify the concept. Finally, the best design is selected at a ‘design evaluation meeting.’ The final outcomes in this phase are the 3D CAD data of outer shape and a design mock-up. Engineering designers do not take any action in this phase. Mostly, they are not even aware of what the industrial designers are designing.

第一階段(概念設計-I):工業設計師獨立開發產品的概念,而不受其他部門的干擾。他們主要關注與美學外觀和用戶體驗有關的方面。他們很少考慮內部零件,這給了他們很多自由。他們為外部和高質量渲染圖像生成3D CAD數據以測試該概念。最終確定外觀形式後,他們會生成一個“設計模型”,一個無功能的原型,以驗證該概念。最後,在“設計評估會議”上選擇最佳設計。此階段的最終結果是外形的3D CAD數據和設計模型。工程設計師在此階段不採取任何行動。通常,他們甚至不知道工業設計師在設計什麼。

2nd phase (ProductPlanning): The product planningdepartmentdecides onthe commercialization of the selected design as well as on the target market, target price and material cost of the design. Finally, they prepare a product-planning document and establish a specific direction for commercialization of the design.

第二階段(產品計劃):產品計劃部門決定所選設計的商業化以及目標市場,設計的目標價格和材料成本。最後,他們準備一份產品計劃文件,並確定設計商業化的具體方向。

圖6:

3rd phase (Concept Design-E/Shape Modification): The product planning document from the previous phase and the final 3D CAD data developed by industrial designers are the initial inputs given to the engineering designers. Engineering designers review the feasibility of the design concept proposed by the industrial designers due to which engineering designers gather relevant technologies and arrange inner parts in the 3D CAD data to test if all indispensable internal functional parts can be fixed inside the exterior form. Sometimes, engineering designers produce experimental prototypes to test if the desired performance can be implemented with the pre-set exterior form. As industrial designers did not consider the internal parts in defining the exterior form, engineering designers have trouble in arranging the inner parts within the given form. Thus, modifying the exterior form is somehow unavoidable. Therefore, there is a corresponding process to Concept Design-E: ‘Shape Modification’ by industrial designers. Industrial designers use the layout data received from engineering designers to modify the exterior form. At this point, two goals collide with each other. Industrial designers try to maintain the original form, while engineering designers demand the modification to ensure functionality and performance. In this process, a very close interaction takes place. The outcome is 3D CAD data about the exterior form and interior part layout.

第三階段(概念設計-E /形狀修改):前一階段的產品規劃文檔和由工業設計師開發的最終3D CAD數據是向工程設計師提供的初始輸入。工程設計人員回顧了工業設計人員提出的設計概念的可行性,因為工程設計人員收集了相關技術並在3D CAD數據中佈置了內部零件,以測試是否可以將所有必不可少的內部功能零件固定在外部表格中。有時,工程設計人員會生成實驗性原型,以測試是否可以通過預設的外觀形式實現所需的性能。由於工業設計師在定義外觀形式時未考慮內部零件,因此工程設計師在將內部零件佈置在給定的形式中時遇到了麻煩。因此,以某種方式不可避免地要改變外觀。因此,Concept Design-E有一個相應的過程:工業設計師的“形狀修改”。工業設計師使用從工程設計師那裡收到的佈局數據來修改外觀形式。此時,兩個目標相互碰撞。工業設計人員嘗試保持原始形式,而工程設計人員要求進行修改以確保功能和性能。在這個過程中,發生了非常緊密的交互。結果是有關外部形狀和內部零件佈局的3D CAD數據。

4th phase (Detail design testing & production/Follow-up): From this phase, engineering designers lead the process in all parts. Engineering designers decide on individual parts’ geometry and compositional structure based on the 3D CAD data determined at the previous phase. Due to the consideration of mass production or reliability testing, they sometimes ask industrial designers to make minor modifications of the exterior design. Upon completion of the detailed design, working prototypes called ‘engineering samples’ are produced to check the form and functionality. At this point, industrial designers evaluate to what extent the exterior form has been produced in compliance with their design concept. Then, engineering designers decide on suppliers, produce moulds, and test ‘pre-production prototypes’ through multiple event processes to improve the reliability of performance and the durability of the product.

第四階段(詳細設計測試和生產/跟進):從這一階段開始,工程設計師在所有零件中領導該過程。工程設計人員根據上一階段確定的3D CAD數據來決定各個零件的幾何形狀和成分結構。由於考慮了批量生產或可靠性測試,他們有時會要求工業設計師對外觀設計進行較小的修改。詳細設計完成後,將生產稱為“工程樣品”的工作原型,以檢查形式和功能。在這一點上,工業設計師要評估其外觀設計符合其設計理念的程度。然後,工程設計師決定供應商,生產模具,並通過多個事件過程測試“生產前原型”,以提高性能的可靠性和產品的耐用性。

On the other side, in ‘Follow-up,’ industrial designers decide on how to apply colour, graphics, material, and surface finishing to the product and provide relevant specifications for engineering designers. For each working prototype produced, industrial designers test the aesthetic and emotional quality with the specifications. When they give their approval, their official role in the design process ends. Unless they give an approval, engineering designers should produce and test the parts in a question again. We found that all six companies have this mechanism for maintaining the design quality of products.

另一方面,在“跟進”中,工業設計師決定如何在產品上應用顏色,圖形,材料和表面修飾,並為工程設計師提供相關規範。對於所生產的每個工作原型,工業設計師都會根據規格測試美學和情感品質。當他們批准時,他們在設計過程中的正式作用就結束了。除非獲得批准,否則工程設計師應再次生產和測試有問題的零件。我們發現所有六個公司都具有這種機制來維持產品的設計質量。

Type 1 is opposed to the conventional belief that a new product development process starts by identifying market needs via market research, or by developing new technology. It starts with pure industrial designers’ conceptualization with full freedom. This implies that new products can be developed based on pictures that industrial designers envision in their minds. This is inconsistent with product design processes described in the engineering design discipline (e.g. in Dym, 1994; Haik & Shahin, 2010; Pahl et al., 2007), where industrial designers’ roles in concept design are missing.

類型1與傳統觀念相反,傳統觀念認為新產品開發過程是通過市場研究或開發新技術來確定市場需求而開始的。它始於純粹的工業設計師的完全自由的概念化。這意味著可以根據工業設計師在腦海中設想的圖片來開發新產品。這與工程設計學科中描述的產品設計過程不一致(例如,Dym,1994年; Haik&Shahin,2010年; Pahl等,2007年),在工業設計中,工業設計師在概念設計中的作用缺失。

Considering the related theories which suggest that creativity happens before the thorough analysis of the problems in a solution-oriented approach (Wynn & Clarkson, 2005), such as ‘primary generators’(Darke, 1979), and the conjecture-analysis model (Hillier, Musgrove, & O’Sullivan, 1972), and other related findings and argument from Lawson (2006) and March (1984), that would be best strategies for a company to give industrial designers freedom and autonomy in generating creative solution concepts without external interference. In fact, Type 1 is employed in two situations: one is to develop new concept products in both shape and function, including the development of new product categories (as in Companies A and E), and the other is to launch a new model of an existing product as quickly as possible (as in Company C). The latter case appears to be possible when there are abundant reference designs so that industrial designers are able to decide on product sizes and exterior elements without any product specification when the lead-time is short.

考慮到相關的理論,即創造力是在以解決方案為導向的方法(Wynn&Clarkson,2005)對問題進行徹底分析之前發生的,例如“主要生成器”(Darke,1979)和猜想分析模型(Hillier)。 ,Musgrove和O'Sullivan,1972年),以及Lawson(2006年)和March(1984年)的其他相關發現和觀點,這將是公司在沒有外部影響的情況下,賦予工業設計師自由和自主權來產生創造性解決方案概念的最佳策略。干擾。實際上,類型1在兩種情況下被使用:一種是開發形狀和功能都新的概念產品,包括開發新產品類別(如公司A和E中的產品),另一種是啟動新概念產品。盡快(如公司C中)的現有產品。當參考設計豐富時,後一種情況似乎是可能的,因此,工業設計師可以在交貨時間短時確定產品尺寸和外部元素而無需任何產品規格。

2.2 Type 2: ID-led Combined Outside-inside Process The companies use this process to develop new types of products or modify existing ones. In either case, unlike in Type 1, the product planning team starts the process. We can explain Type 2 in four phases as shown in Figure 7.

2.2類型2:由ID領導的組合內外流程 公司使用此過程來開發新型產品或修改現有產品。在任何一種情況下,與類型1不同,產品計劃團隊都將啟動該過程。我們可以分四個階段來解釋類型2,如圖7所示。 圖7:

1stphase(ProductPlanning):Theproductplanningteamcreatesaproductplanning document to initiate a product development. It sets up a target market, target price, and product specification. When developing a modified version of existing products, itdecides on them in linewiththe existingproducts, including those of competitors. When developing a new product, engineering designers helpdecideonthem.Theoutcomeofthisphaseisaproductplanningdocument.

第一階段(產品計劃):產品計劃小組創建一個產品計劃文檔以啟動產品開發。它設置了目標市場,目標價格和產品規格。在開發現有產品的修改版本時,它會根據現有產品(包括競爭對手的產品)來決定它們。在開發新產品時,工程設計師會幫助他們確定。此階段的結果是產品規劃文檔。

2nd phase (Concept Design-I): Upon receiving the product planning document from the product planning department, industrial designers decide on the product’s exterior and related interior. They collect functional items needed for the product being developed in compliance with the product size and specification, and also derive form concepts from research on users or design trends. Then, they arrange the interior parts to decide on the exterior form while avoiding any collision between the interior parts and the intended exterior form. Thus, they go back and forth between the outer shape design and the arrangement of the inside parts. There was a little interaction between industrial designers and engineering designers in this phase. For the final event, design evaluation proceeds with non-functional design mock-ups. Thus, the outcome in this phase is the 3D CAD data concerning the exterior form and the initial interior layout of the product, and a design mock-up.

第二階段(概念設計-I):從產品計劃部門收到產品計劃文件後,工業設計師將決定產品的外觀和相關內部。他們收集符合產品尺寸和規格的待開發產品所需的功能項目,並從對用戶或設計趨勢的研究中得出形式概念。然後,他們安排內部零件以決定外觀形式,同時避免內部零件與預期的外部形式之間發生任何衝突。因此,它們在外形設計和內部零件的佈置之間來回移動。在此階段,工業設計師和工程設計師之間幾乎沒有互動。對於最終事件,設計評估將使用非功能性設計模型進行。因此,此階段的結果是有關產品外觀和初始內部佈局的3D CAD數據,以及設計模型。

3rd phase (Concept Design-E/Shape Modification): Upon receiving the 3D CAD data from industrial designers, engineering designers closely inspect the feasibility and operability of the interior parts in connection with the exterior form and develop the final layout. While engineering designers check them, and frequently request industrial designers to modify the layout or the outside form. Thus, industrial design activities proceed with a corresponding process; ‘Shape Modification.’ However, the form change is not as significant as in Type1 because they decided the exterior form in connection with the interior parts in the previous phase. The outcome in this phase is the 3D CAD data about the final exterior form and the definitive layout of the interior parts.

第三階段(概念設計-E /形狀修改):從工業設計師那裡獲得3D CAD數據後,工程設計師會仔細檢查內部零件與外部形狀相關的可行性和可操作性,並製定最終佈局。工程設計師檢查它們時,經常要求工業設計師修改佈局或外部形式。因此,工業設計活動要進行相應的過程。 “形狀修改”。但是,形狀更改不像Type1那樣重要,因為他們在上一階段決定了與內部部件相關的外部形狀。該階段的結果是有關最終外觀形式和內部零件確定佈局的3D CAD數據。4th phase (Detail design testing & production/Follow-up): This phase is not significantly different from that in Type 1.第四階段(詳細設計測試和生產/跟進):該階段與類型1並無顯著差異。

A notable characteristic of Type 2 is industrial designers’ active involvement in arranginginnerfunctionalcomponentswhiledecidingtheoutershapeinthe2nd phase. Although industrial designers’ knowledge of thelinkage between interior layout and the outer shape is less engineering-focused, this case clearly demonstrates that the role of industrial designers has extended beyond what we normallyexpect.Asaresult,theindustrialdesignersbecomeinfluentialandtake the initiative in decision-making. In addition, engineering designers are hardly involved in this phase. We expected that layout design would be an exclusive job of engineering designers, as suggested by the engineering design literature (e.g. Hubka & Eder, 1987; Pahl et al., 2007; Ullman, 2009). We assumed that atleastengineeringdesigners would activelyprovide adviceandguidancefor industrial designers. However, they expected the data to arrive from industrial designers and granted industrial designers freedom to complete outside form in connection with the inside structure of a product. The design-first policy of the company seems to be the main reason at this point.

類型2的顯著特徵是工業設計師在確定第二階段的外形時積極參與佈置功能性組件。儘管工業設計師對內部佈局與外部形狀之間的聯繫的了解較少以工程為重點,但此案例清楚地表明,工業設計師的作用已經超出了我們通常期望的範圍。因此,工業設計師變得很有潛力並且可以主動地進行決策。此外,工程設計師幾乎沒有參與此階段。根據工程設計文獻的建議(例如Hubka&Eder,1987; Pahl et al。,2007; Ullman,2009),我們希望版圖設計將是工程設計人員的專屬工作。我們假設至少工程設計人員會積極為工業設計師提供建議和指導。但是,他們希望數據能夠從工業設計師那裡獲得,並賦予工業設計師自由完成與產品內部結構有關的外部形式的能力。此時,公司的設計第一政策似乎是主要原因。

2.3 Type 3: ED-led Inside-first Process Type 3 is different from Type 1 and Type 2 in two points: they use it only to redesign the existing products, and engineering designers’ activities proceed prior to industrial designers. It requires a more prominent role for engineering designers while reducing the role of the industrial designers. We explain their characteristics as follows:

2.3類型3:由ED主導的內部第一個過程類型3與類型1和類型2有兩點不同:它們僅用於重新設計現有產品,工程設計人員的工作要先於工業設計人員進行。它要求工程設計師扮演更重要的角色,同時減少工業設計師的角色。我們解釋它們的特徵如下:

1st phase (Product Planning): As shown in Figure 8, the product planning team firstly initiates the product development project based on the annual roadmap of product development. At this point, they do have a functional concept of the products in the roadmap. Product planning experts determine the target market, target price, product size, and material costs based on the existing products in the market. Frequently engineering designers help them develop the product specification by analysing technical parts of competitors’ products and estimating the material cost. The outcome of this phase is the product-planning document, which includes product specification.

第一階段(產品計劃):如圖8所示,產品計劃團隊首先根據年度產品開發路線圖啟動產品開發項目。至此,他們在路線圖中確實具有產品的功能概念。產品規劃專家根據市場上現有的產品確定目標市場,目標價格,產品尺寸和材料成本。工程設計人員經常通過分析競爭對手產品的技術部分並估算材料成本來幫助他們開發產品規格。此階段的結果是產品計劃文件,其中包括產品規格。

2nd phase (Concept Design-E): Engineering designers rapidly develop a preliminary layout based on the product specification. They commonly use the data of previously developed products. Upon its completion, they send the preliminary layout as 3D CAD data to industrial designers. This is the starting point of industrial design process. Industrial designers use it as an input to develop the exterior form, while engineering designers seek solutions for system performance and continue to refine the layout. As the interior layout and the exterior form develop simultaneously, both teams closely interact and discuss any points of disagreement or conflict, and repeatedly exchange feedback for modification. Eventually, the preliminary layout becomes the definitive layout while the design sketch develops into the definitive exterior form. The outcome in this phase is the definitive layout reflecting the final size of the product being designed.

第二階段(概念設計-E):工程設計師根據產品規格快速制定初步佈局。他們通常使用以前開發的產品的數據。完成後,他們將初步佈局作為3D CAD數據發送給工業設計師。這是工業設計過程的起點。工業設計人員將其用作開發外觀的輸入,而工程設計人員則尋求系統性能的解決方案並繼續完善佈局。隨著內部佈局和外部形式的同時發展,兩個團隊密切互動並討論任何分歧或衝突之處,並反復交換反饋以進行修改。最終,當設計草圖發展為確定的外觀形式時,初步佈局成為確定的佈局。這個階段的結果是確定設計的最終佈局,從而確定最終產品的尺寸。

2.5th phase (Concept Design-I): This process is far from an independent subsequent phase but rather an intermediary phase between the second and the third. Thus, we shall call it the 2.5th phase. It starts upon the receipt of preliminary layout from engineering designers and progresses concurrently with Concept Design-E. The industrial designers check the interior layout and overlay with a matching exterior form. They undertake idea sketches, 3D CAD modelling, rendering, design evaluation meetings, and a mock-up selection event to decide on theexterior form design. Engineeringdesigners keep advisingand evaluating ontheexteriorform.Assuch,theexteriorformand layoutdeveloplittlebylittle through the intertwined Concept Design-I and Concept Design-E.

2.5階段(概念設計-I):此過程遠非一個獨立的後續階段,而是第二和第三階段之間的中間階段。因此,我們將其稱為第2.5階段。它從收到工程設計人員的初步佈局開始,並與Concept Design-E同時進行。工業設計師檢查內部佈局並以匹配的外部形式進行覆蓋。他們進行構想草圖,3D CAD建模,渲染,設計評估會議和模型選擇活動,以決定外觀設計。工程設計人員不斷為外觀設計提供建議和評估。因此,外觀設計和佈局通過相互交織的Concept Design-I和Concept Design-E逐步發展。

3rd phase (Detail designtesting and production/Follow-up): This phase is not markedly different from that in Type 1 and Type 2.

第三階段(詳細設計測試和生產/跟進):該階段與類型1和類型2沒有明顯不同。

All companies except Company B used this process. This indicates that it is most widely used. Interviewees noted that this process is comparable to the companies’ official guidelines for design processes in terms of roles, tasks, and stages. However, they mentioned that the actual period is shorter than that specified in the guidelines.

除公司B以外的所有公司都使用此過程。這表明它被最廣泛地使用。受訪者指出,就角色,任務和階段而言,此過程可與公司有關設計過程的正式指導方針相媲美。但是,他們提到實際時間比指南中指定的時間短。

2.4 Type 4: ID&ED Synergetic Process

Type 4 took place not by official proposal but individual designers’ efforts in the early phases. In many cases, engineering designers involved in developing line-up models tend to reject novel design concepts proposed by industrial designers, because of feasibility issues within the limited time. To implement the concepts, industrial designers work with engineering designers who are freer. Therefore, this process makes it possible to continue with novel design concepts that were rejected. In addition, industrial designers and engineering designers make synergic efforts. Breaking away from the conventional separated approach, they handle a design concept in an integrated way considering many design variables concurrently. The detailed phases of this process are as follows):

2.4類型4:ID&ED協同過程類型4並非是根據官方提議而發生的,而是各個設計師在早期階段的嘗試。在許多情況下,由於在有限的時間內存在可行性問題,參與開發陣容模型的工程設計師往往會拒絕工業設計師提出的新穎設計概念。為了實施這些概念,工業設計師與自由設計師合作。因此,此過程使繼續拒絕的新穎設計概念成為可能。此外,工業設計師和工程設計師也可以協同工作。與傳統的分離方法不同,它們以集成方式處理設計概念,同時考慮了許多設計變量。此過程的詳細階段如下):

圖8:

1st phase (Concept Incubation): As in Figure 9, industrial designers conceive of a new design independently. They mostly build it from the design ideas that were excluded from proceeding projects despite their innovativeness.

第一階段(產生概念):如圖9所示,工業設計師獨立地構思新設計。他們大都是根據僅有創新性但仍未開始進行的設計構想來構建它。

2nd phase (Concept Design): This phase starts when industrial designers seek engineering designers who can work with them. When an engineering designer agrees to join the industrial designer for implementing the design concept, they work closely throughout this phase. The engineering designer provides stateof-the-art technology for the industrial designer to sharpen the design concept. The first level of inside layout is developed based on the outer shape that is being developed. The outcomes of this phase are the 3D CAD data about the exterior form and interior layout.

第二階段(概念設計):此階段始於工業設計師尋找可以與他們合作的工程設計師。當工程設計師同意加入工業設計師以實施設計概念時,他們將在整個階段中緊密合作。工程設計師為工業設計師提供最先進的技術,以增強設計理念。內部佈局的第一層是根據要開發的外部形狀開發的。該階段的結果是有關外觀和內部佈局的3D CAD數據。

3rd phase (Product Planning): Product planning team decides commercialization of the design via a design evaluation meeting. Then, the product planning team defines the target market for the design. From this phase, the engineering designers in charge of developing line-up models become involved.

第三階段(產品計劃):產品計劃小組通過設計評估會議來決定設計的商業化。然後,產品計劃團隊確定設計的目標市場。從這個階段開始,負責開發陣容模型的工程設計人員就參與其中。4th phase (Detail designtesting & production/Follow-up): The process of this phase is not much different from that in Types 1, 2, and 3.第四階段(詳細設計測試和生產/跟進):該階段的過程與類型1、2和3的過程沒有太大不同。

The existing product development environment causes engineering designers to be conservative. Most development projects in the domain of consumer electronics are urgent. Companies usually set a product launch day in their plans. Thus, designers execute all tasks and events following the timeline to the day. Based on the interview data, engineering designers involved in these kinds of projects tend to reject novel design concepts proposed by industrial designers, because they feel that they could not ensure their work with the concepts pass the performance and reliability tests by the chosen time. The failure of the testing will directly influence the company’s product development roadmap as well as the engineering designer’s annual performance when evaluated. This seems to make them select and evaluate design concepts conservatively. Therefore, this process is hardly available to the designers who are directly involved in projects proceeding on a timeline to the market. Conversely, engineering designers who are relatively free from the timeline to the market, for example, those involved in developing advanced technology for future products will be more open to novel design concepts. Besides, more importantly it seems that designers who are more open-minded to collaborative works with other experts tend to execute this process.

現有的產品開發環境使工程設計人員趨於保守。消費電子領域的大多數開發項目都是緊迫的。公司通常會在計劃中設定產品發布日。因此,設計人員將按照時間軸執行所有任務和排程。根據訪談數據,參與此類項目的工程設計師傾向於拒絕工業設計師提出的新穎設計概念,因為他們認為自己無法確保使用這些概念的作品能夠在選定的時間通過性能和可靠性測試。測試失敗將直接影響公司的產品開發路線圖以及工程設計師評估時的年度績效。這似乎使他們保守地選擇和評估設計概念。因此,對於直接參與按時間表進入市場的項目的設計人員來說,幾乎無法使用此過程。相反,相對而言,從時間表到市場的時間相對有限的工程設計師,例如那些參與開發面向未來產品的先進技術的工程師,將更願意接受新穎的設計理念。此外,更重要的是,似乎更願意與其他專家合作進行設計的設計師傾向於執行此過程。

In the case of Company D, Type 4 had a great market success with a new product by employing this process. However, further cases actively applying this process to following projects were not reported in our interview. Nonetheless, it is interesting that Company D dispatched several engineering designers from the advanced technology development team to a neighbouring office of the industrial design team. This enabled the synergetic process case. The top management purposely moved them to prevent industrial designers producing unrealistic design concepts by letting them provide necessary technical supports promptly for industrial designers. This seems to stimulate both parties to be more intimate, thereby creating a cooperative mood. This will increase the possibility of emerging integrated design processes.

對於公司D,通過採用此過程,類型4在新產品方面取得了巨大的市場成功。但是,在我們的採訪中沒有報告更多將這一過程積極應用於後續項目的案例。儘管如此,有趣的是,D公司還是從先進技術開發團隊派遣了幾名工程設計師到工業設計團隊的一個相鄰辦事處。這啟用了協同處理案例。最高管理者故意讓他們動用,以使他們迅速為工業設計師提供必要的技術支持,以防止工業設計師提出不切實際的設計概念。這似乎激發了雙方更加親密,從而營造了合作的氣氛。這將增加新興的集成設計流程的可能性。

3 .Discussion and implication3.

討論與啟示

3.1 Role change

3.1角色變更

Industrial designers’ contribution is dominant in the concept design phase and afterward, engineering designers take over their major role. This can be regarded as the general characteristics of the four types of design processes. With the exception of Type 3, all the design processes started with design concepts developed by industrial designers. In the case of Type 1 and Type 2, industrial designers independently define the design concept in terms of shape and use. Type 4 is integrative in the concept design phase, but starts with the industrial designer’s initial design concept. Unlike the other three types, Type 3 cases, where the scheduled modification of existing products happens, start with the layout design by engineering designers. It appears that their roles are divided as concept developers and concept implementers. Interestingly, as a company pursues new concept products or emphasizes emotional feeling and usability even in re-design cases, the role of industrial designers seems to be significant. This is a different phenomenon from the idea that a new concept product is developed through the development of new principles and technology. They rather devised new uses or the meaning of existing ones. Therefore, this can be viewed as evidence that new design also starts with existing technologies and principles.

工業設計師的貢獻在概念設計階段占主導地位,此後,工程設計師接任其主要角色。這可以視為四種設計過程的一般特徵。除類型3外,所有設計過程均始於工業設計師開發的設計概念。對於類型1和類型2,工業設計師根據形狀和用途獨立定義設計概念。 Type 4在概念設計階段是集成的,但從工業設計師的初始設計概念開始。與其他三種類型(第3種情況)不同,在這種情況下,對現有產品進行了計劃中的修改,首先是由工程設計師進行佈局設計。看來他們的角色分為概念開發者和概念實現者。有趣的是,當一家公司追求新概念的產品或強調情感感覺和可用性(即使在重新設計案例中)時,工業設計師的作用似乎很重要。這與通過開發新原理和新技術來開發新概念產品的想法不同。他們寧願設計新用途或現有用途的含義。因此,這可以被視為新設計也從現有技術和原理開始的證據。

Regarding industrial designers’ knowledge, counter to our belief that they would rarely consider inside parts, they seem to have enough knowledge to read and handle the inside functional components and carry out the outside design. Except for Type 1, defining the outside shape always happens through considering and rearranging the inside functional parts by industrial designers. Type 2 is an unexpected case. Industrial designers develop the outer shape by arranging the related inside components at the same time. However, their work on the inside parts was probably limited to major parts that directly affect the outside shape. Although, they were not fully involved in designing the details of inside parts, it is apparent that their role was extended to the area of engineering design. It is attributed to the top management’s strong support to industrial design and the shared CAD tools between both groups.

關於工業設計師的知識,與我們認為很少考慮內部零件的信念相反,他們似乎具有足夠的知識來閱讀和處理內部功能組件並進行外部設計。除類型1外,定義外部形狀通常是通過工業設計師考慮並重新佈置內部功能部件來進行的。類型2是意外情況。工業設計師通過同時安排相關的內部組件來開發外形。但是,他們在內部零件上的工作可能僅限於直接影響外部形狀的主要零件。儘管他們沒有完全參與設計內部零件的細節,但是很明顯,他們的作用已擴展到工程設計領域。這要歸功於最高管理層對工業設計的大力支持以及兩組之間共享的CAD工具。

3.2 Selection of design approach

3.2選擇設計方法